In the Packaging industry there are many different ratings, certifications and drop testing that can be done to deem a package safe for shipping. But safe from what?

To design an effective and safe packaging solution, you need the weight of the item, fragility (G-Force) and the shipping method. With this information, in most cases, you can design a solution that will protect your product from being damaged in transport.

The important trap to avoid is over-engineering the packaging.

In many circumstances, less is more. Having 12’’ of polyurethane foam all around a glass vase seems like a great idea, but in fact a drop test proves differently. All the impact, otherwise call G-Force, will be transmitted to the glass vase and it will most probably explode on impact.

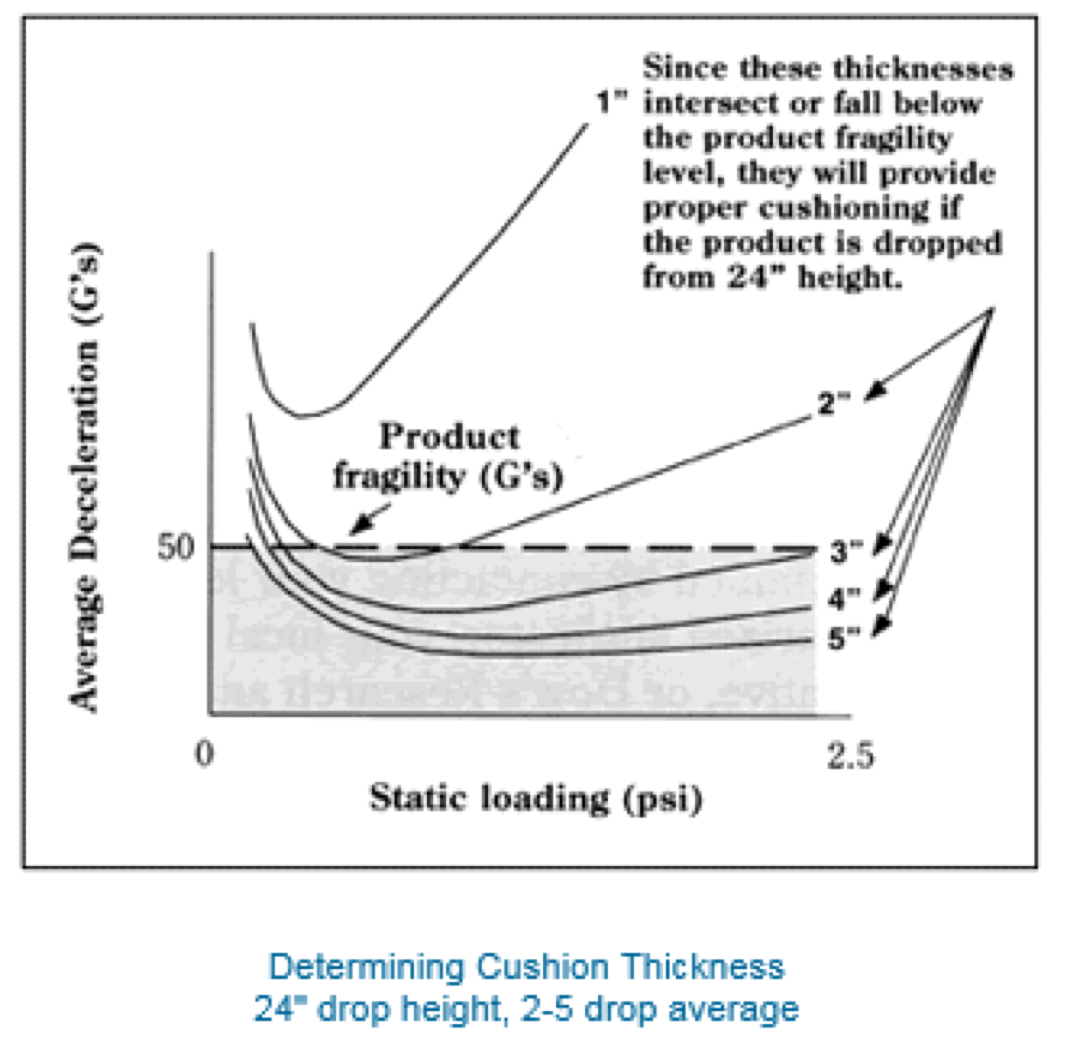

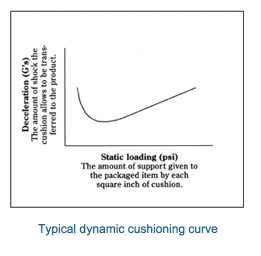

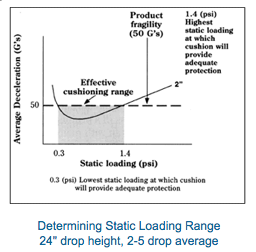

The solution is to use the dynamic cushioning curves chart to calculate the material of any given thickness and how it behaves during different impact conditions. Specifically, the portion of the design which directly supports the load and functions – to absorb shock during impacts. There may be additional material used in the design assembly, like the outer container to help reduce the g-force effect on the inner package.

Using the correct materials at right thickness and density with a design that allows for g-force dispersion within the packaging will permit the item to survive and pass most drop test with flying colors.

Must Reads:

https://www.westpak.com/images/pdf/04_package_drop_testing_dos_donts_of_package_impact.pdf

https://www.westpak.com/images/pdf/11_cushion_material_testing.pdf