At Lovepac, we design custom protective packaging solutions using a variety of materials to ensure products arrive safely. Two of the most common options are polyethylene foam and corrugated inserts. Each offers distinct advantages depending on your product, shipping conditions, and budget.

Polyethylene foam is a highly reliable material for protecting products during transit. It is lightweight, durable, and engineered to absorb shock and impact. Foam inserts, sheets, and end caps provide excellent cushioning, making them ideal for fragile, high-value, or sensitive items. One of foam’s biggest advantages is its ability to be fully customized to the exact shape and size of a product, ensuring a snug fit that prevents movement and damage. Polyethylene foam is also moisture-resistant and reusable, making it a strong option for long-term or repeat-use packaging. However, foam solutions can be more expensive than corrugated alternatives and may not be necessary for less delicate products.

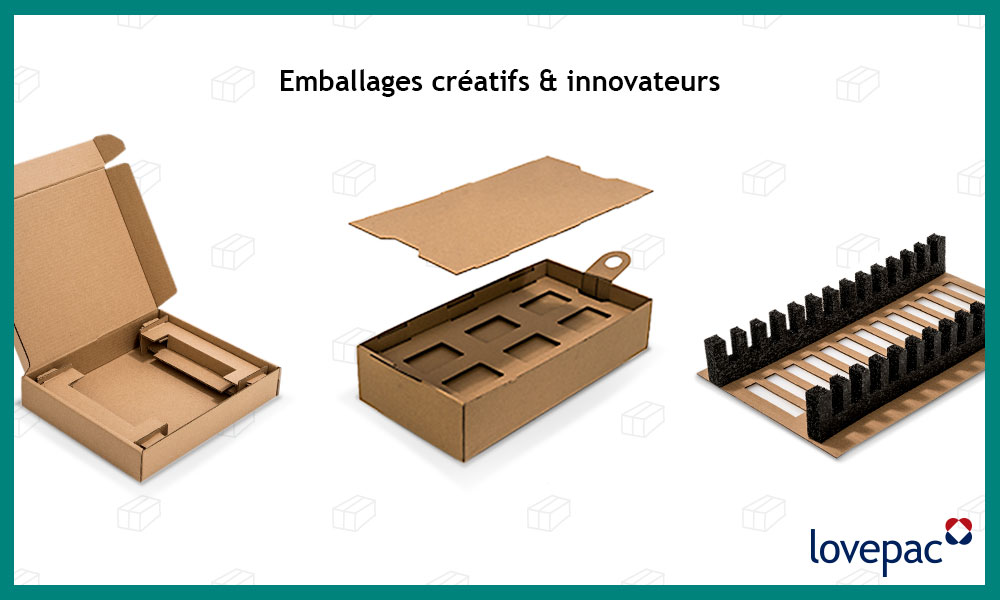

Corrugated inserts, on the other hand, are a cost-effective and environmentally friendly solution. Made from paper-based materials, they are lightweight, recyclable, and well-suited for products that need basic protection and organization within a box. Corrugated inserts work well for separating items, preventing surface scratches, and providing structural support. While they offer less shock absorption than foam, they are an excellent choice for durable products or short shipping distances. The main limitation is reduced protection against heavy impacts or vibration.

Choosing between foam and corrugated inserts depends on your product’s fragility, shipping environment, and protection requirements.

At Lovepac, we help you select and design the right solution to balance performance, sustainability, and cost.

Contact us today to get a custom quote for your packaging project.